Bio diesel for Next generation Micro-emulsified Hybrid Fuel

An advance treatment without any chemical reaction and utilizing glycerin as well.

1.Plants cost less than 1/3 (one third )of the FAME

2.Producing cost is less than JPY 10 per a liter

3.Stabilization for heating and long storage

4.Compact and possible to operate on-site

5.Enable to use with any kinds of vegetable oil,animal fat and mineral oil

6.Producing the fuels adding water is possible *

*The fuels adding water is enable for ships or big scale diesel engine like power generator

Conventional Bio diesel:BDF

FAME:Fatty Acid Methyl Ester technology

To improve the performance of spraying fuels, it requires to be removed glycerin of

vegetable oil by chemical reaction. Accordingly, there are below shortcomings enough

hard to utilize.

1.Producing plants cost expensive

2.High cost for producing(JPY 20〜50 per a liter)

3.Quick deterioration, and it cannot stand preservation for long time

4.Requiring disposal of draining like glycerin or drainage

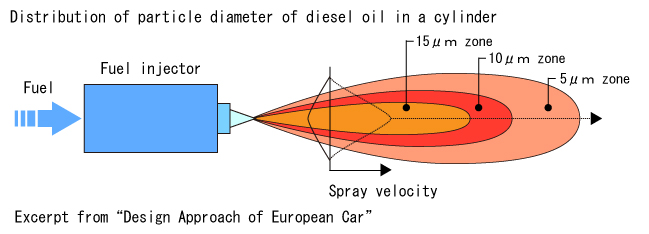

Diesel spray in a cylinder

グリセリンを含んだ状態でも、このように超微粒子化された燃料が均一拡散して燃焼します。

Analysis Certification

[title of the test] waste food oil with / without micro-emulsification treatment

[date of the test] 8 December 2004

[analysis objective] investigate the possibility and availability of waste food oil as a 「diesel fuel」

[analysis result]

| Original | After treatment | |

| density 15℃ g/cm3 | 0.9264 | 0.9263 |

| flash point (PMCC) ℃ | 222 | 202 |

| viscosity (Kinematic) cSt,50℃ | 26.42 | 26.07 |

| moisture (Karl-Fischer) | 0.38 | 0.23 |

| sulfate wt.% | 0.06 | 0.05 |

| pour point ℃ | -5.0 | -7.5 |

| carbon residue wt.% | 0.41 | 0.38 |

| ash wt.% | under 0.01 | under 0.01 |

| 90%distillation test ℃ | failure | failure |

| cetane index | failure | failure |

| energy Cal./g | 10,550 | 10,570 |

| energy J/g | 44,180 | 44,250 |

|

|

|---|---|

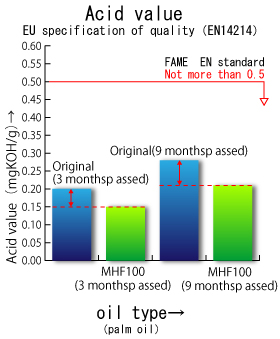

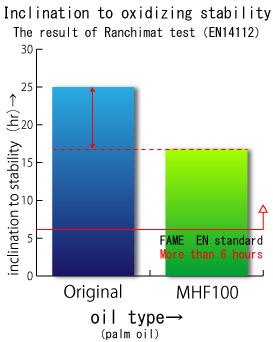

| 製造後9ヶ月経過しているのも関わらず、規定値を大幅に下回っている。大変安定した状態を示している。 | ランシマットによる加速劣化試験において、EN規格の6時間以上に対し、16、8時間と3倍近い安定度を示しており、高温時の劣化が極めて少ないことを証明している。 |

|

|

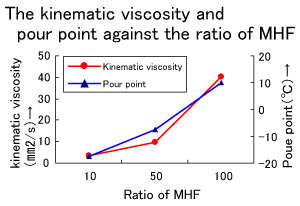

| MHFの最大の課題は粘度が高いことにあるが、軽油との混合使用することで大幅に改善できることを示している。 このデータの原料油はパーム油であるにもかかわらず、MHF50は十分な特性を持っています。 |

|

Potential customers for introducing MHF

1.Who can raise available, reasonable and enough vegetable oil for themselves

・Virgin vegetable oil is ideal, but waste vegetable oil is also available*

*Some waste vegetable oil may require cleaning & purifying devices according to their conditions.

2.Who can personally consume the fuels which they produce.

・Setting mixed ratio with gas oil as around 50% enable to huge cost down.

3.Who can apply the fuels to heavy machines, farm machines or generators.

・Making possible to reduce black smoke drastically, and there is almost no change with fuel consumptions.

Some examples of customers who have already been introduced MHF in Japan

Ex.1

The middleman of treating industrial waste Utilizing MHF as a fuel for heavy machine which

operate at the treatment plant of incinerating dirty mad from sewerages,

and use waste oil as a fuel for assisting incinerations. Achieved the goal of

both reduction with cost and CO2.

Ex.2 Large-scale MHF producing enterprise

|

|

|---|---|

|

|

Near future Bio fuel which MHF realize

・Cultivating Jatropha that leads producing many quantity of inedible oil and MHF can bring us green oil field which never dry up.

・We have already completed technical verification, and it says there is no difference with power or exhaust gas from gas oil.

・It is possible to on-site operation at Jatropha plantation by using small-size MHF machine.

・It is no more just a dream after we got the combination of Jatropha and MHF with very cheap producing cost to green by planting Jatropha in desert areas.

|

|

|---|---|

| Jatropha seeds | The oil expeller |

|

|

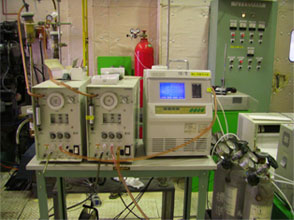

| The small size MHF machine 50L/H |

Accurate estimation

・Excellent Result is proved

(1)「MHF50」(軽油50、植物油50)の燃料で、低負荷から最大負荷の全域で軽油100%とほぼ同等の燃料消費量でした。

(2)排気ガス性状も良好です。

|

|

|---|